They were packing them in at the famous Winslow pub on Goodison Road on Friday night, reminiscent of the Everton FC we knew.

Neville Southall, Derek Mountfield, Peter Reid and Paul Bracewell were signing old photographs and shirts, before a street event at the People’s Club bar, Goodison’s Park End stand.

There, Reid and Bracewell, engine room that side, discussed some fantastic days and nights on the old ground. There was a reverent silence as they paused at the legendary 3-1 victory over Bayern Munich, which helped Everton win the European Cup Winners’ Cup, in 1985. The talk sold, of course.

Looking back is something Everton fans have to do more and more these days, because it really isn’t worth thinking about the future.

All the headlines have revolved around sustainability rules and points deductions, with the club facing an independent Premier League commission for the third time this week. But that noise has obscured the more significant scandal of how Everton has been brought to the brink of insolvency by Iran-born, Monaco-based Farhad Moshiri, a fool at the club’s wheel since 2016, whose custody has caused the Glazers to flee. look very good. in comparison, competent owners.

Everton’s potential owners have been asked to prove access to more than £400m (777 co-founder Josh Wander, pictured with Genoa manager Alexander Blessin)

The demands of the Premier League are so important that 777 is unlikely to meet them

Your browser does not support iframes.

We discovered at the weekend that Moshiri, who spent £750m to no material effect before his Putin-supporting business partner Alisher Usmanov was sanctioned and the cash ran out, is demanding to keep at least £64m, rising to a possible £130m, from US investment company 777.

The sum is far greater than anyone is willing to pay Moshiri, which explains why all the credible buyers have left and 777 has been pacing the directors’ box, considering the idea of being the keeper of the keys. , when their dismal record at other clubs suggests they shouldn’t be anywhere near the place.

At Standard Liège there are unpaid salaries. The threat of a transfer ban in the Brazilian club Vasco da Gama. Genoa have to crowdfund a £4m training camp. 777 is directed by Josh Wander, who was recently cited by a Danish model who alleges that he took and shared a “non-consensual explicit photograph” of her. Wander denies it.

On Saturday morning, there was a ray of light amidst all this darkness for Everton, although fans had to be extremely optimistic to spot it.

The Premier League has been considering whether 777 are suitable to own the club for six months and the Bloomberg agency revealed details of the financial guarantees they have been ordered to provide.

The figures don’t make sense to many fans (£185m in cash, a £345m loan), but the demands are so substantial that 777 probably won’t be able to meet them. Everton’s chief financial analyst, The Esk, tells me that he believes there is only a five per cent chance of the takeover happening. “The way the 777 is viewed in the investment community, I also find it hard to believe that another company will join them,” he says.

The short-term consequences could be serious. If no other buyer is found to pay what Moshiri demands, the club could become insolvent and go into administration, leading to an additional points deduction, because repayment of a major loan falls in April and Moshiri certainly won’t pay it. That would still be preferable to the 777.

The legacy of the Moshiri era at Everton could be a first spell outside the top flight since the early 1950s and the job losses that come with insolvency. However, that is not a certainty.

If no other player is found to pay what Moshiri demands, the club could become insolvent and go into administration, resulting in a further points deduction.

There are other potential buyers behind the scenes, including an American investor, with the funds, management experience and a track record in American sports franchises and European soccer. And administration is not the end.

“Everton have the ability to bounce back, given we have a new stadium almost completed, a huge fan base and a lot of untapped potential,” says The Esk. ‘If we technically went bankrupt, we would survive. We would return.’

However, much of the collateral damage from this miserable Moshiri period cannot be undone. Let’s think of Graeme Sharp, legend of the 80s team and Everton’s top scorer in the post-war period.

Accepting a request from the late Bill Kenwright to join the board as an ‘advisor’ and link himself to better times, he found himself unfairly associated with the club’s mismanagement, was discredited and eventually told to stay away for his own safety.

The legacy of the Farhad Moshiri era could be a first period outside the top flight since the early 1950s

It looks like Everton could prevent the daylight robbery and, at some point, a new dawn will dawn.

Sharp was left devastated and is still away from the club he loves; a legend whose appearance at a recent reunion of members of the 1984 FA Cup-winning team was actually a surprise to some of those former teammates, who feared that this fracture meant he would not join them.

‘I’m so glad you came out!’ they told the man whose image dominates the outside wall of the stadium on Goodison Road. Sharp’s role on the board was not to make decisions, although those shouting “Sharp Out” had no appreciation of that.

A few doors down from the Winslow on Friday, a sign in the window of one of the red brick terraces said all about the fate that has threatened the terribly diminished and vulnerable Everton. ‘Theft hotspot’.

It looks like Everton could prevent the daylight robbery and that at some point down the line, a new dawn will dawn for them. After these long years of hell and with more obstacles to come, it is currently difficult to see it that way.

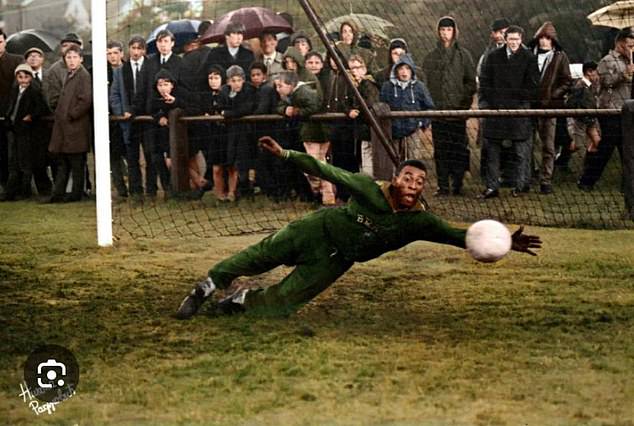

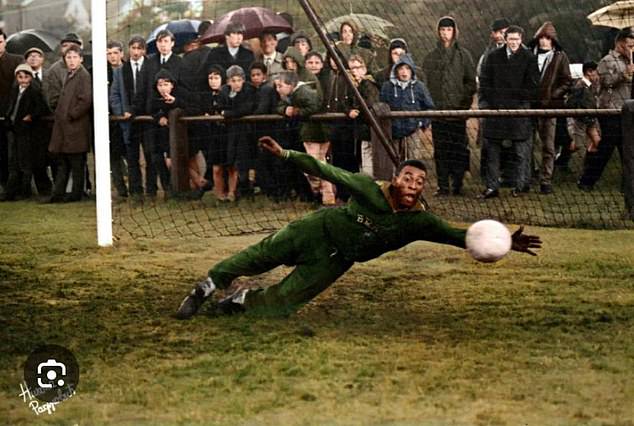

Pelé’s image explains England’s problems

I wrote about the story of the England v Brazil match last week, speaking to people who could help me understand why England had won so few.

Reader Matthew Rimmer, whose father, Warwick, was a Bolton defender, sent me this photo of Pelé training in the rain in the old Lancashire town during the 1966 World Cup, and it all became clear.

Brazil thrived on a wonderfully simple love of the game, radiating from that Burnden Park image.

This image of Pelé training in the rain in Bolton in 1966 makes it clear why England have a dismal record against Brazil.

Time is everything

It is curious that Umbro’s decision to change the color of the St George’s flag on the England shirt in 2011, splashing it with mini four-colour crosses, has not caused any murmur.

And Team GB’s kit for the 2016 Olympics included a union flag with no red at all, barely registering. Proof that timing is everything.

barely registered.

Nike’s controversial England shirt (pictured) has plenty of criticism, but there were few rumors surrounding the 2011 England shirt or Team GB’s kit for the 2016 Olympics in Rio, Brazil.

England’s Euro 2012 kit designed by Umbro and Peter Saville features the St George’s flag in four different colors on the upper back of the shirt: red, blue, green and purple.

The morning ritual will never be the same

The letter, typed on blue paper, was heartbreaking in its own way. He revealed that our kiosks will close starting next month.

They have delivered our newspapers for almost 20 years, although it was during our ritual Saturday morning visit to the place that my grandson and I saw Panini stickers and decided to collect.

The thud of papers on the mat provokes a thrill of anticipation that has never diminished with time. Thank you so much, Marian and Linda, from Woods Paper Shop, Handforth, Cheshire. The morning ritual will never be the same.