Table of Contents

How do you solve a problem like masculinity? All that anger! All that violence! All that inherent misogyny that every child has bubbles up inside him!

Well, according to the Labor Party, male ‘influencers’ are installed inside classrooms in the hope that they can teach other boys how to behave around women.

Bridget Phillipson, the party’s education spokesperson, has pledged to introduce the plan as a response to the rise in sexual harassment in British classrooms after the pandemic; a response, so to speak, to Andrew Tatheification of modern man.

In case you don’t know, Andrew Tate is a 6-foot-3 former kickboxing champion and social media personality, who, ironically, has been banned from almost every social media platform in existence for his hateful opinions.

He has been hailed as the “king of toxic masculinity” and recognized as one of the loudest voices in the “manosphere”, the collective term given to blogs, forums and websites that promote masculinity and, in some cases, encourage violence against women.

Learning a lesson: Labour’s education spokesperson has pledged to install male ‘influencers’ in schools in response to the post-pandemic rise in sexual harassment in British classrooms.

Make no mistake, Andrew Tate is not a good guy; After all, he currently languishes in Romania awaiting trial for rape and human trafficking, accusations he denies.

The Luton-born 37-year-old is, by all indications, a self-proclaimed misogynist and routinely shocks and incites with comments as ridiculous as suggesting women should “take responsibility” for having been sexually assaulted.

How is it possible then that he has become a figurehead for thousands of men around the world? I think the answer is that men (and schoolboys in particular) are tired of being told to be more like women. And Andrew Tate, with his abs, his flash cars, and his ability to do a near-perfect tornado kick, is one of the few male voices unafraid to stand up for masculinity.

As far as I can see, masculinity has been under siege for the last decade; Many see it as a problem to be solved. The MeToo movement has spawned a fourth wave of feminists with zero tolerance for “boys will be boys” behavior, leading an entire generation of young people to question their every interaction with the opposite sex.

Just before Christmas, I found myself talking to a young friend at a party. He’s a decent guy: smart, kind, and deeply respectful of women. He was explaining to me how confused he gets when he dates someone.

Like a growing number of men in their twenties, there is something consciously unmasculine about him. There’s a softness to his voice, a gentleness that was never there when I was growing up with children.

When I broached the subject, she said, ‘This is how we think women want us to be. More like them…’ She then went on to explain how so many men she knows feel unable to be themselves; masculinity has such a bad reputation in 2024. They are trying anything to present themselves as less of a “classic man.”

That night I lay in bed feeling desperately conflicted. On the one hand, shouldn’t we celebrate men being more in touch with their feelings? On the other hand, I thought about all the times I’d heard the phrase “toxic masculinity” uttered by young women in front of men.

I thought about what kinds of characteristics society currently attributes to “good men”: vulnerable men, men who are in touch with their emotions, men who prefer book club to martial arts. Men who basically look a little more like women.

And this, I guess, is what really worries me. Because the more we point to male identity as the problem as opposed to specific examples of criminal behavior, the more some men will back off and turn to characters like Andrew Tate.

So what is the answer? Well, she would start by suggesting that what is needed is compassion, not anger. And celebrate the good in men: ambition, drive, strength (yes, I know, women have these traits too) instead of admonishing them for the bad.

But most of all, I think understanding that men feel lost and rejected or angry as hell should be the start of the solution. Imposing a government-trained ‘influencer’ on them to explain why everything they are doing is wrong probably isn’t.

Nobody buys your vulnerable side, J-Lo!

Do they have any money. They have appearance. They have power. But what’s the one thing celebrities are still craving in the 2020s? Vulnerability.

First up was Beyonce’s Renaissance documentary (hey, she’s a hard-working forty-something like you, well, except for the £600 million in the bank).

Then, Posh and Becks revealed (almost) everything on Netflix’s Beckham.

Fiercely capable: Jennifer Lopez with husband Ben Affleck in Los Angeles this month

Now J-Lo has spent $20 million on a combination documentary titled The Greatest Love Story Ever Told, which addresses aging, insecurities and her two-decade love story with husband Ben Affleck.

J-Lo has always struck me as the most fiercely capable woman, so trying to weave an alternative narrative seems a little hollow to me.

Can you remember your PIN?

Last week, I was purchasing groceries with my card when the cashier handed me the merchant’s keypad and asked me to enter my PIN number.

Memory test: almost one in five people no longer remember their PIN

Cue a cold chill running down your spine. I have been without contact for years and it turns out that I am with almost one in five people who no longer remember their PIN.

So yeah, I came out empty-handed and red-faced.

Is it just me or is the entire world “unchained” or “exploring its limits”? Therapeutic language is the language chosen by Generation Z, for whom feelings triumph over all else; So is it any wonder that a new survey shows that 5 percent of young adults are now out of work for mental health reasons? Meanwhile, if another person tells me that he is “sharing her truth,” I myself will run to the nearest therapist’s couch.

The real message behind Anya Snap

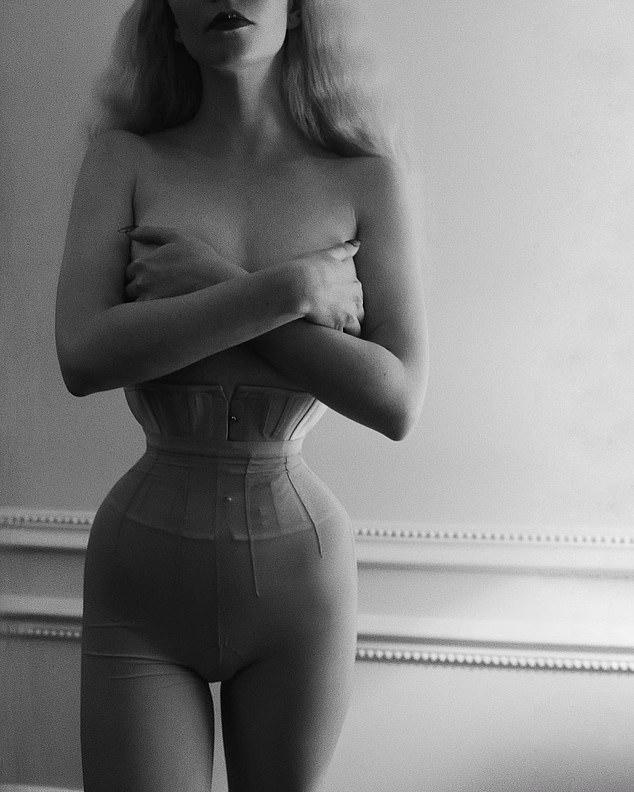

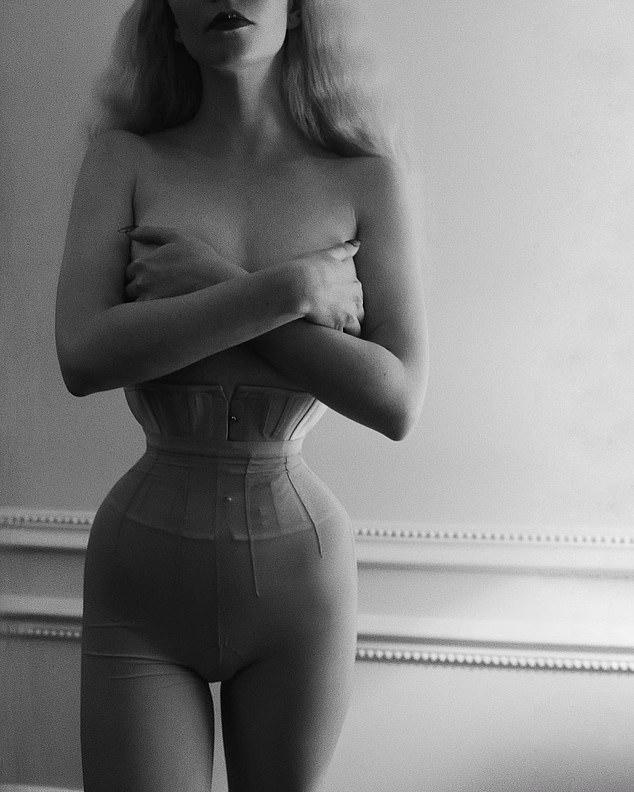

This week, Hollywood star Anya Taylor-Joy came under fire for sharing a photo of her tiny waist cinched even tighter by a corset (pictured) on her Instagram account.

While some jumped to her defense, the overall message was clear: After a decade of body positivity, we should know better than to praise thinness.

Cinched: The image posted by Anya Taylor-Joy last week showing her wearing a corset

However… at last week’s Milan Fashion Week there was a notable return to slimness on the catwalks, with few medium- and plus-size models making the cut. Then there is the fact that Ozempic use is widespread.

If culture swings in one direction, the only certainty is that it will eventually recede in the other.