<!–

<!–

<!– <!–

<!–

<!–

<!–

Most parents are constantly looking for creative ways to make their lives easier while keeping their children happy.

And now, moms and dads from all over the world are sharing their genius tips online – and Bored panda has collected a selection of the best examples in a gallery.

They include a creative idea of putting half a smiley face on each of the children’s pairs of shoes so they can match the image and make sure they are on the right feet.

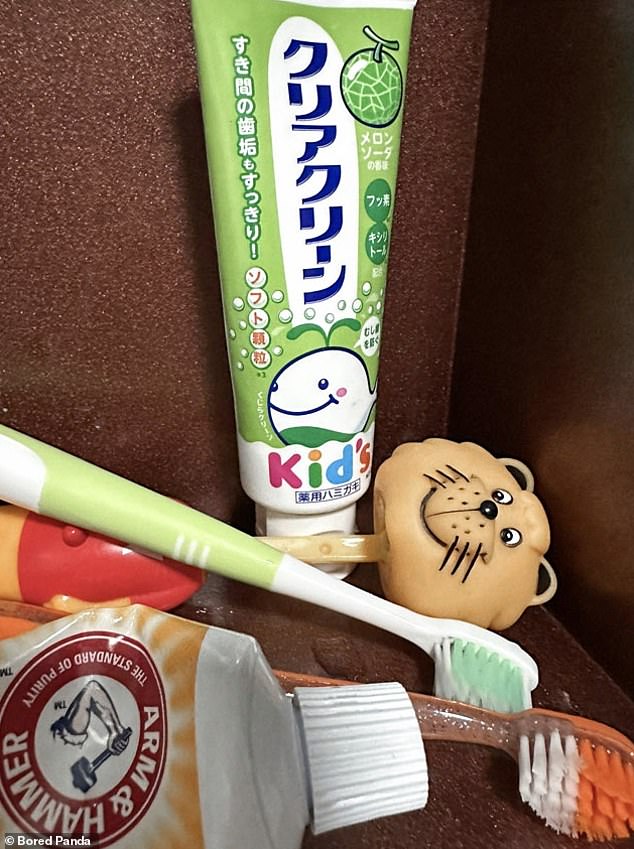

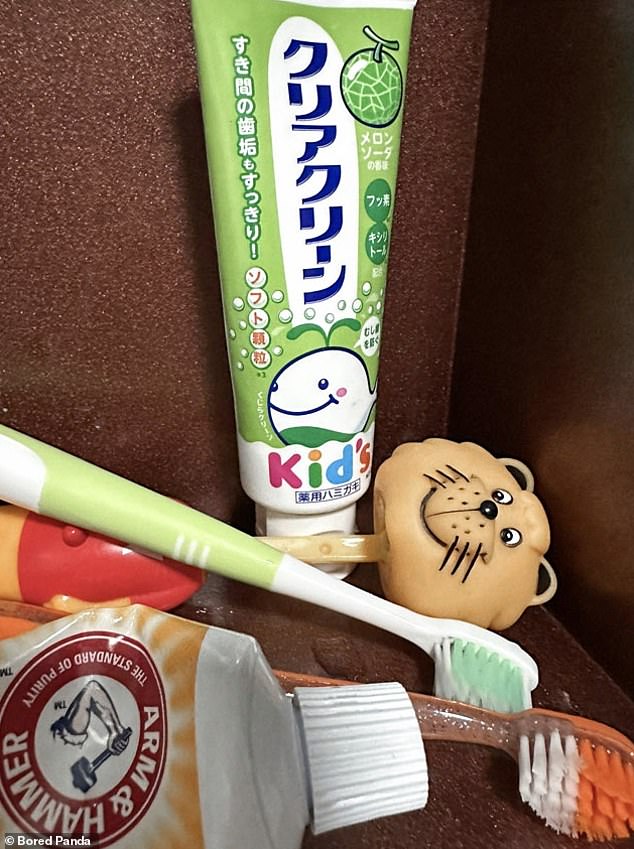

Elsewhere, in Shanghai, a father gave his son three toothbrushes and two toothpastes to allow him to choose which one to use, giving him a false sense of control over brushing his teeth.

Moms and dads from all over the world have been sharing their genius parenting tips online and Bored Panda has put them together in a gallery. They included a clever way to keep kids’ fingers clean by using a cupcake wrapper to catch the melting ice cream drops (pictured).

Another awesome idea came from a mother who uses the “loudest cruncher competition” to get her kids to eat vegetables, allowing them to “choose their vegetable weapon” to bite into.

Elsewhere, a mother in France found the perfect way to hide Ben & Jerry’s ice cream from her kids in the freezer.

She simply placed the containers in empty vegetable packages, knowing they would never be pilfered.

Examples include a creative idea of putting half a smiley face on each of the children’s pairs of shoes so they can match the image and make sure they are on the correct feet.

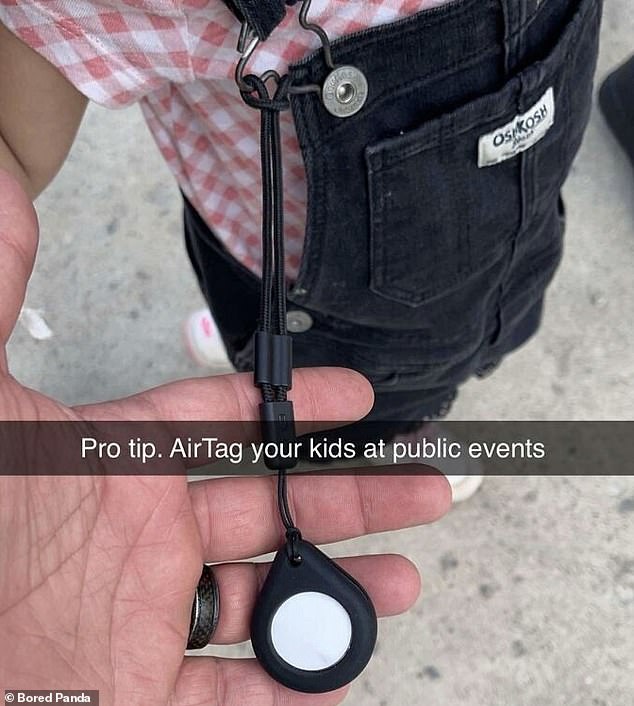

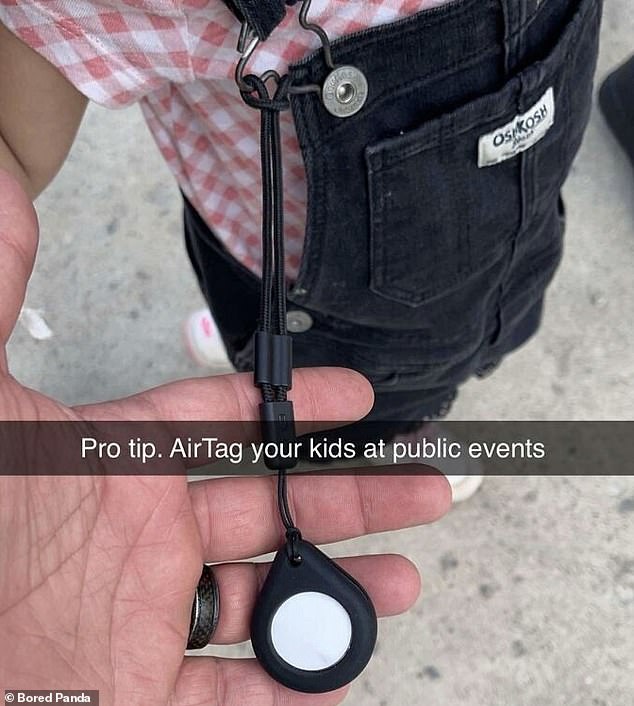

Elsewhere, a father decided to tag his child at a public event so he could track him if he ran away.

Another awesome idea came from a mother who uses the “loudest cruncher competition” to get her kids to eat vegetables, allowing them to “choose their vegetable weapon” to bite into.

Another clever parent learned to trick their child into thinking they’re having a cup of tea, but prefer sweets.

In France, a mother found the perfect way to hide Ben & Jerry’s ice cream from her children in the freezer

Elsewhere, in Shanghai, a father gave his son three toothbrushes and two toothpastes to allow him to choose which one to use, giving him a false sense of control.

Meanwhile, a simple game called “hands on the circle” keeps these kids safe when they get out of their cars so they don’t run away.

Meanwhile, this mother decided to use a large wooden ruler to stop her child from opening drawers.

Have you ever had trouble determining which cast was which? This parent separated them into bags and stuck a copy on each