A widow has revealed that telling her two daughters their father was “going to die” were the “hardest days of my life”.

Stacey Heale, 44, from Southampton, appeared on ITV’s Lorraine this morning with host Ranvir Singh to discuss her new book, It’s Not the Time for Flowers: What Nobody Tells You About Life , love and loss.

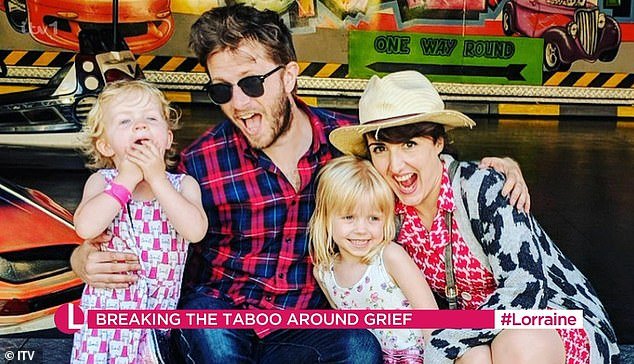

Stacey, a fashion writer, lost her husband, indie band Delays frontman Greg Gilbert, to incurable bowel cancer in 2021 – he was just 44. He left behind his daughters Dali, nine, and Bay, seven.

Since then, she has openly discussed the roller coaster of grief she and her family have endured, and aims to inspire honest discussions about grief and loss through her book.

While sitting with Ranvir, the mother of two opened up about the tumultuous times following Greg’s cancer diagnosis on their daughter’s first birthday.

Stacey Heale has revealed that telling her two daughters that their father was “going to die” were the “hardest days of my life” (pictured: Stacey on ITV’s Lorraine)

Stacey lost her husband, indie band Delays frontman Greg Gilbert, to incurable bowel cancer in 2021 – he was just 44. He left behind his daughters Dali, nine (left) and Bay, seven (right)

She said: “When he (Gregg) died, they (my daughters) were five and seven… the hardest days of my life, I would say, was the day we had to tell them that he was going to die.

“When we found out, when we were told that he had a few weeks to live, we had to tell them obviously and how we talk to kids in these spaces is really important.

“We like to think that they don’t really know what’s going on, but they do, they really do because they feel things and really need to be told in a very factual way what’s going on.” .

The widow detailed her experiences trying to overcome grief and loss, which she said was “complicated” at times.

She added: “When I was going through my husband Greg’s terminal cancer diagnosis, I was looking for stories that reflected back to me how I was feeling – which was complicated and messy. And I didn’t find that.

“I found a lot of voices saying five steps of what to say to someone who was grieving, or very methodical ways of going through it, and it didn’t reflect how I felt at all.”

She then talked about her children’s constant “flips,” which she explained as “jumping in and out” of their emotions instead of confronting them head on.

In her book, she notes that children may show interest in activities such as playing outside with a next-door neighbor or going to the park, but she cautions parents not to confuse this with “resilience.” .

Since her husband’s death, Stacey has openly spoken about the roller coaster of grief she and her family have endured.

During the show, she talked about her children’s constant “flips,” which she explained as “going in and out” of their emotions instead of confronting them head on.

“I’ve seen this with my own eyes with my own children, like telling them their father was going to die,” she told Ranvir.

“And a few minutes later they say, ‘Can we go play in the yard?’ »

“I discovered it’s called puddle jumping: that’s where kids just don’t have the brain capacity to handle those emotions to be able to jump in and out of them …and then they have to move on.”

Stacey also revealed the unlikely place she found comfort after her husband’s diagnosis.

The couple first learned of Gregg’s fate on their youngest daughter’s day, Bay’s first birthday, and Stacey later attended chemotherapy support groups while she was still breastfeeding.

Feeling out of place among those in their 70s, she turned to social media where she discovered an “incredible community” of people facing similar experiences.

Dame Deborah James, who was diagnosed with stage three bowel cancer at the age of 35, became “a great friend” to Stacey before she died aged 40 in 2022.

The fashion writer, 44, from Southampton, appeared on ITV’s Lorraine this morning with host Ranvir Singh (left) to discuss her new book, It’s Not the Time for Flowers: What no one tells you about life, love and loss.

She notably discovered Dame Deborah James, who was diagnosed with stage three bowel cancer at the age of 35 and who became “a great friend” before passing away at the age of 40 in 2022 .

She recalls: “I didn’t even have a social media account when he was diagnosed, and in particular I discovered this incredible community of people on Instagram who spoke really honestly.”

“Funnily enough, Dame Debs was the very first person I was put in contact with because in fact she and Greg were diagnosed in the same week in 2016.”

She later said she found herself in bizarre fits of laughter when contacting the funeral directors because she “didn’t know what to say to them”, before adding that “we’re all going to go through this”.

Stacey left her career as a fashion academic to care for her husband full-time before he died of bowel cancer in 2021.

Her new book, Now is Not the Time for Flowers: What No One Tells You About Life, Love and Loss Hardcover, will be released March 28, 2024.