- Garron Noone has almost 700,000 people following his views on life in Ireland

- The TikTok star’s foul-mouthed rants have racked up more than 20 million likes online

<!–

<!–

<!– <!–

<!–

<!–

<!–

An Irish comedian has made a hilarious video about an auctioneer’s sale of one of the smallest houses for sale in the country.

The one-bedroom mid-terrace property in Cork city is just 34 square meters and was built around 1900.

It has no on-site parking and only a small backyard. It is currently on sale with auctioneer with a guide price of €170,000 – approximately £145,000.

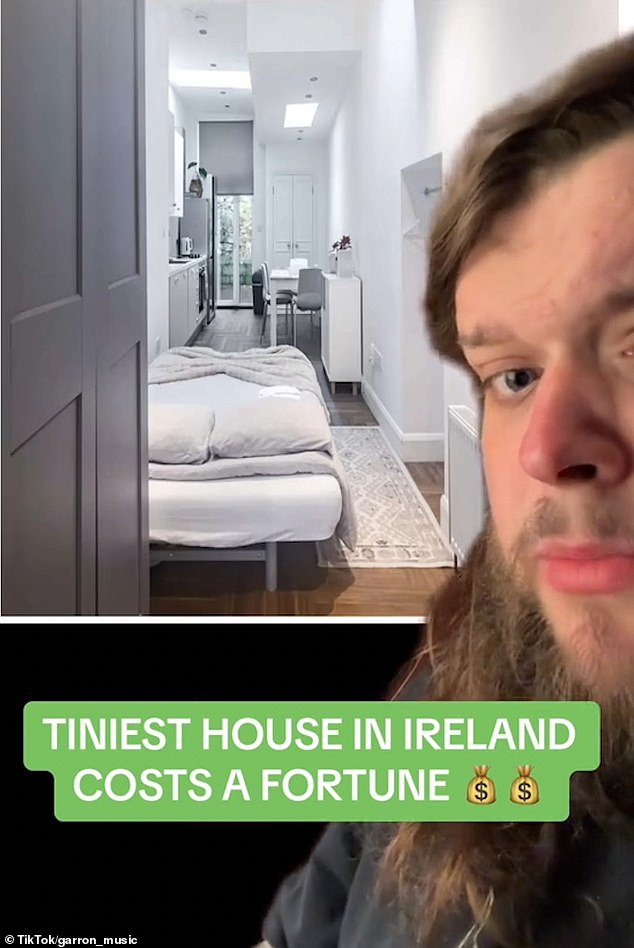

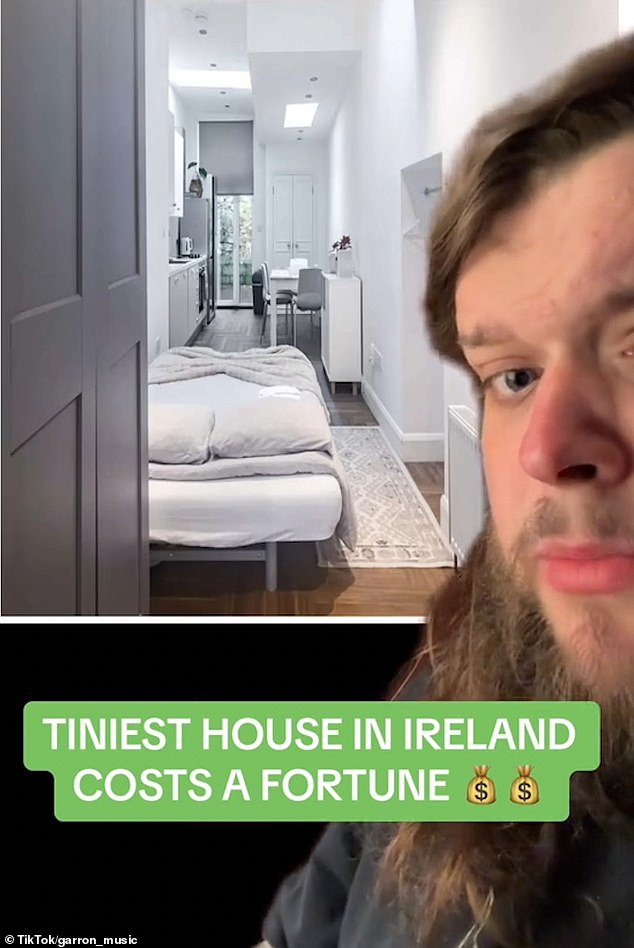

Despite having an extremely modern and elegant interior, the comedian Garron Noone29, from County Mayo, has a cult following on TikTok for his observations on life and Americans’ inability to make a proper cup of tea.

This week, he has had more than 130,000 views for his version of the tiny house for sale in Cork city centre.

Garron Noone questioned how they found a door to fit the front of this £145,000 house in Cork city in Ireland and asked if the window was made by an optician during a 60-second rant.

Garron Noone, pictured right, filmed a 60-second TikTok video mocking the tiny house.

He suggested there was space to store a toblerone or possibly one of the smaller Harry Potter novels in the storage recess in the wall, as shown in the photo on the right.

He begins his video by setting the scene in a fairly conventional way.

“This house is for sale in Ireland for 170,000 euros.”

Soon the tone changes.

It continues in the next clip: ‘For God’s sake… one door barely fits. The window was probably made by an optician.

He then starts vandalizing the property.

Why did you bother installing an alarm system? Nobody is going to steal from you.

Switching to an extreme close-up, he mimics the type of desperate man who would criminally break into such a small abode.

‘Hello, I’ve broken into your house. Come closer so I can take your belongings.’

With still 40 seconds left, Garron continues talking about the outside of the property, which is just a five-minute walk from Cork city centre.

Addressing the heartbroken owner, he continues: “You’ve taken everything I own, my portable DVD player and my four packets of crisps… although I must say I feel quite spacious in here now.”

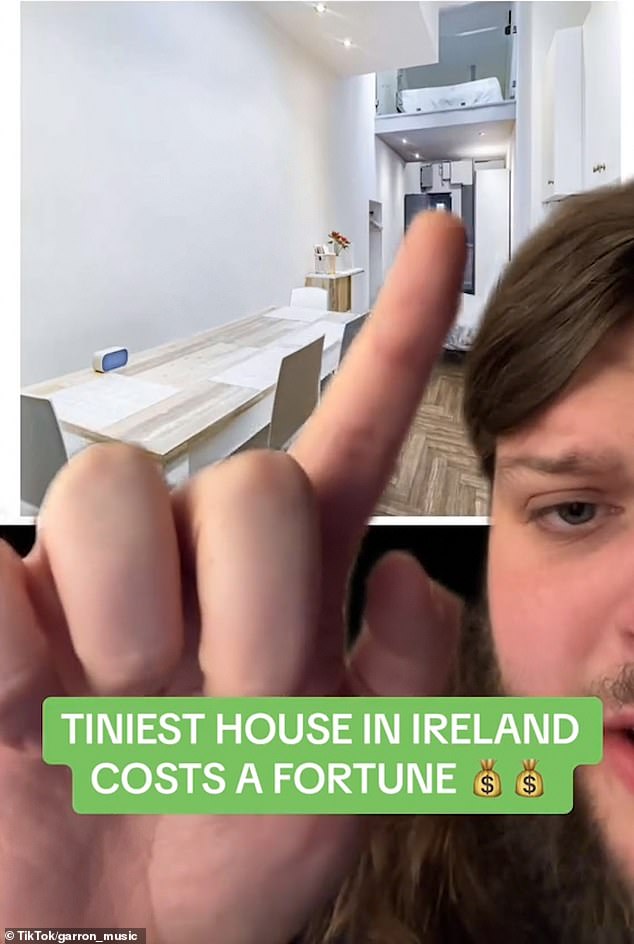

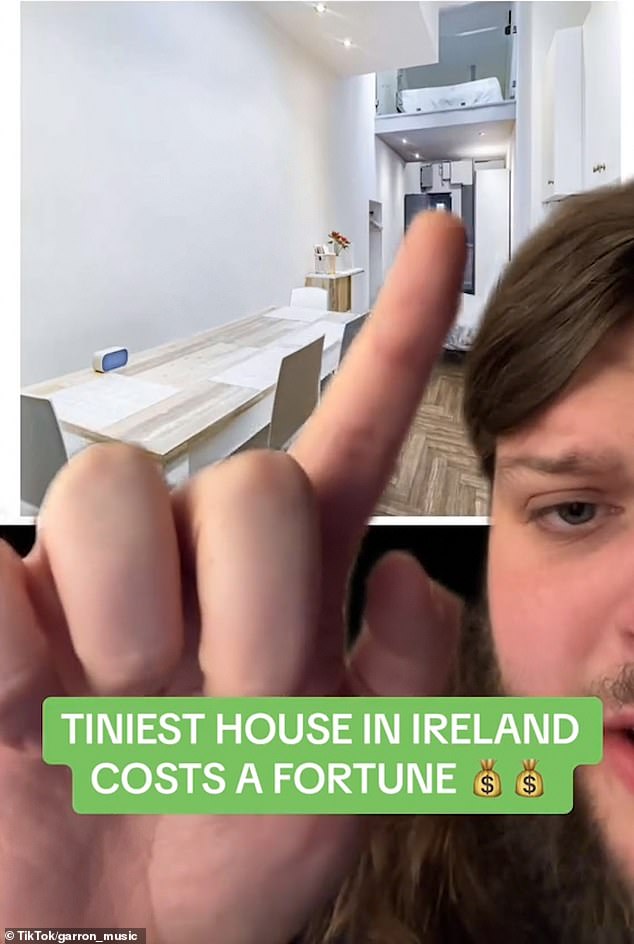

Next, Garron takes a critical look at living space.

“Here’s the inside of the place and it looks like he has his clothes hanging above the door, which of course is fashionable in a modern home.”

Pointing to the split-level layout, he muses: ‘Here, of course, is the master bedroom. I don’t know how you get there, maybe with a rope or a pair of stilts.

He questioned how the new owner was supposed to get into the bed, which is displayed in the two-tiered area above the front door.

He warned of the potential danger of falling out of bed as he pulled a sock out of the small storage closet.

‘Here is, of course, the storage hole in the wall. You could store your Toblerone there or perhaps one of the shorter Harry Potter books.

Returning to the upper level, Garron remains confused about access to the dormitory area, but anticipates potential health and safety issues.

He tells his followers: “I still don’t know how the hell you get here… you definitely don’t want to fall out of bed while retrieving your sock from the little locker next to the bed.”

Having finished his review, Garron decides he could make a cheeky offer on the property.

‘I’ll give you €60 for it… follow me, I’m delicious.’