<!–

<!–

<!– <!–

<!–

<!–

<!–

Timothée Chalamet’s star power has earned him a lucrative deal.

The actor, 28, who is filming a Bob Dylan biopic, has signed a multi-year first-look deal with Warner Bros.

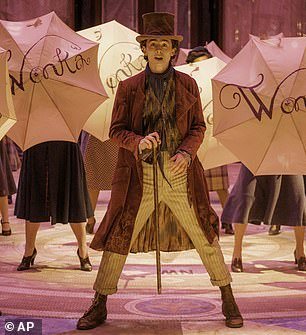

The versatile star topped the box office with recent films Wonka and Dune: Part Two, becoming the first actor in four decades to star in both major domestic films that were released within an eight-month period, according to the studio.

So far, the two films have grossed almost $1.3 billion combined.

In a statement, the sought-after actor said he looked forward to collaborating with the studio again.

‘These are studio heads who believe in making real movies and I’m so grateful for their support as an actor, producer and collaborator. This partnership seems like a natural next step. Let’s go!’ said the boyfriend of makeup mogul Kylie Jenner.

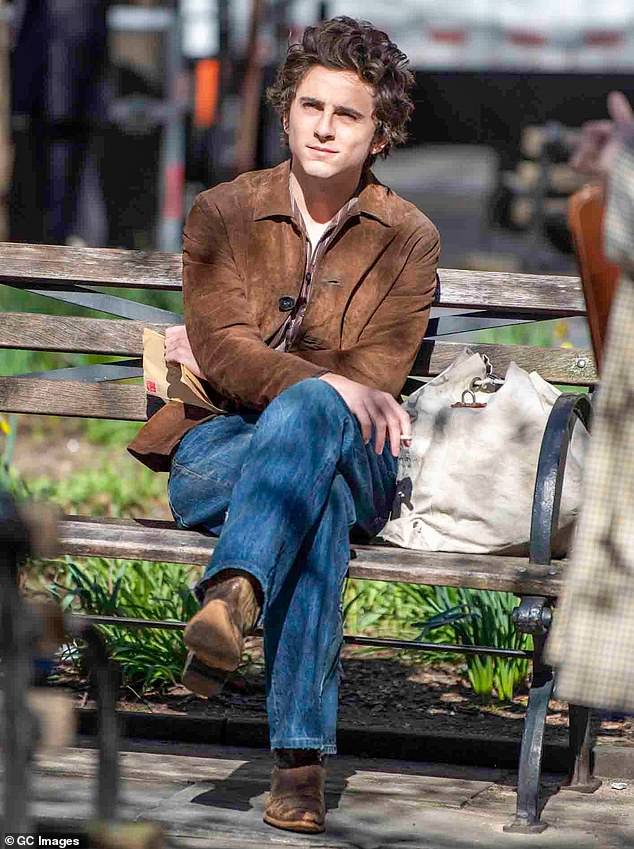

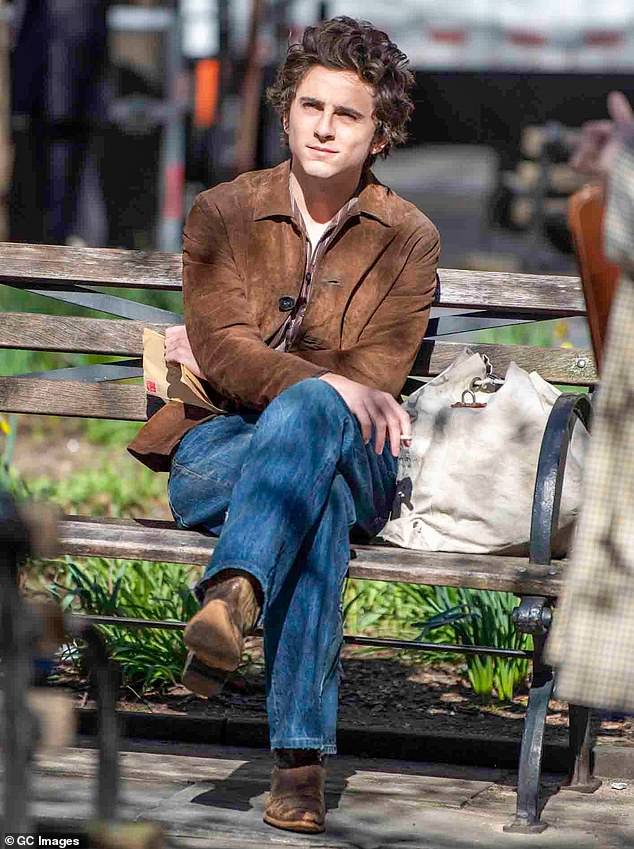

Timothée Chalamet, 28, has signed a multi-year first look deal with Warner Bros (pictured in New York in February)

In a statement released Tuesday, Warner Bros. co-chairmen and CEOs Mike De Luca and Pam Abdy said they were “delighted that Timothée has chosen our studio as his creative home.”

‘Over the last few years, we have admired not only Timothée’s commitment to his craft, which is evident in the variety and depth of his varied roles, but also his unwavering dedication to devoting 100% of his time and attention to every project he undertakes. has. “Made here at Warner Bros. and elsewhere,” they continued.

“Their collaboration on the Dune and Wonka campaigns is something we all enjoyed immensely and the results speak for themselves,” the executives concluded.

The first-look deal allows the Lady Bird star to pursue projects that interest him, and Warner Bros. has the first option to back him.

After steadily building his career with small roles in film and television, the young actor burst onto Hollywood’s radar in 2017’s Call Me By Your Name, a tender drama about a young man who falls in love with an older man who works as an assistant to his father’s research during a summer in Italy.

He earned an Oscar nomination for his performance.

The native New Yorker starred in highly acclaimed films such as Beautiful Boy, Little Women and French Dispatch.

The versatile actor has starred in two No. 1 films, Dune: Part Two and Wonka, becoming the first actor in four decades to star in both major domestic films that were released within an eight-month period, according to the studio.

After steadily building his career with small roles in film and television, the young actor burst onto Hollywood’s radar in 2017’s Call Me By Your Name as a teenager who falls in love with his father’s research assistant. Chalamet received an Oscar nomination for his work

The native New Yorker starred in highly acclaimed films such as Little Women, Beautiful Boy and French Dispatch.

Chalamet got his start as a producer on the gritty cannibal love story Bones and All

The actor is currently filming the Bob Dylan biopic A Complete Unknown and will serve as a producer on the project (pictured in New York on March 24).

He got his start as a producer on the gritty cannibal love story Bones and All, and will play that role again on the Dylan biopic, A Complete Unknown.

The actor has been working with a voice coach and will sing some of Dylan’s songs in the film, according to People.

“It’s kind of surprising because going from the Wonka character to Bob Dylan, it’s a completely different character, a completely different voice, everything, and he does it,” vocal coach Eric Vetro told the outlet. ‘He could change on a dime. He is so talented that he is able to switch from one role to another very quickly.’

A release date has not been announced for A Complete Unknown.